Additive Manufacturing

3D Printing for

Medical Devices is here!

Why 3D Printing?

How to Get Started

5 steps to launch your Medical Device

Step 1

Upload your files (*.step *.slt & *.pdf)

Don't have a file?

We can help here.

Step 2

Select material & finish

for your Medical Device

Step 3

Fine-tune design

DFM to optimize functionality & cost

Step 4

Review Quote

and approve lead-time

Step 5

Print your devices

one layer at a time

Get Started Today!

Why wait any longer?

Email us directly at 3d-printing@intech-medical.com or upload your models in form attached to quote your next project leveraging our state-of-the-art 3D-printers dedicated to Medical Devices in an ATEX controlled environment.

DMP Flex 350

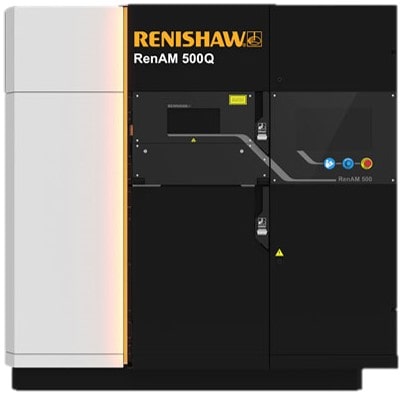

RenAM 500Q